Volta Labs

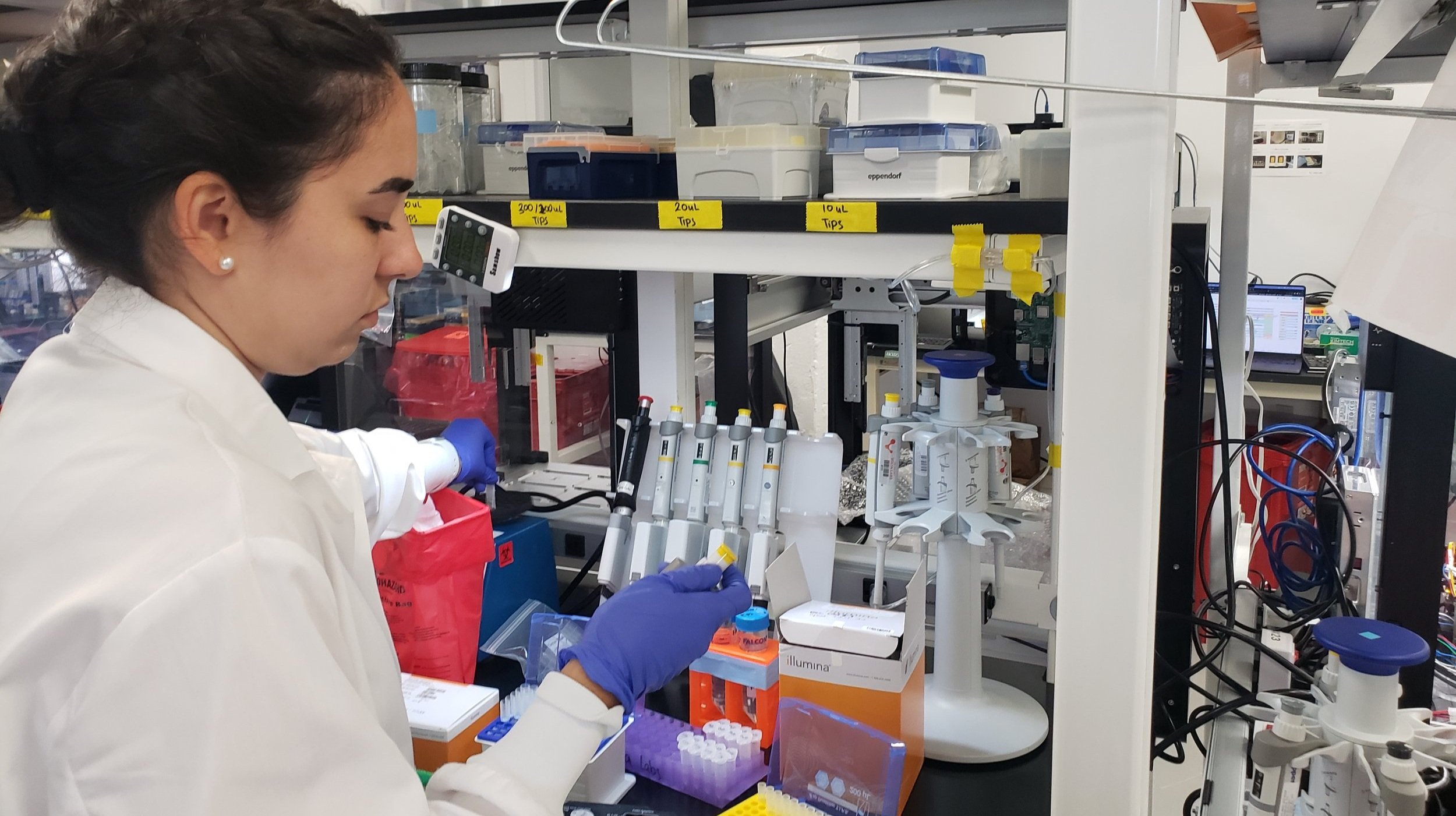

I worked as a contract industrial designer for Volta Labs, a startup from MIT that developed a automated DNA extraction workflow to transform the originally manual and time-consuming process. I worked to create the user experience, appearance, and mechanics of the exterior housing and internal labware for their main product: Callisto machine.

Info:

Contract Work

2023 Summer, 9 weeks

Volta Labs

Supervisor/Teammate

Raymond Lin

Gina Zhang Quincy Kuang

Create concept sketches and physical mockups

Design and conduct user testing

Design the internal machine labware

Skills:

Industrial Design; Physical Prototyping

Tools:

Solidworks; Figma; 3D Printing; Model Making

Role:

Research: Observation

We conducted observations of DNA extraction process and user interactions with the engineering prototype to understanding their specific pain points, such as difficulty accessing the screen and high demand for cognitive load.

Research: Order Of Operation

By observing the user interactions of the work-like prototype, we compiled the general workflow of the Callisto machine, analyzing levels of user involvement in different stages of machine flow, how they parallel with the manual operation, and points of mistrust behind the “Black Box” machine.

Research: Identify Pain Points

Delving deeper into the user experience of the engineering prototype, we identified the pain points throughout different stages of the machine operation. This helped us prioritize the directions for our design and prototyping efforts.

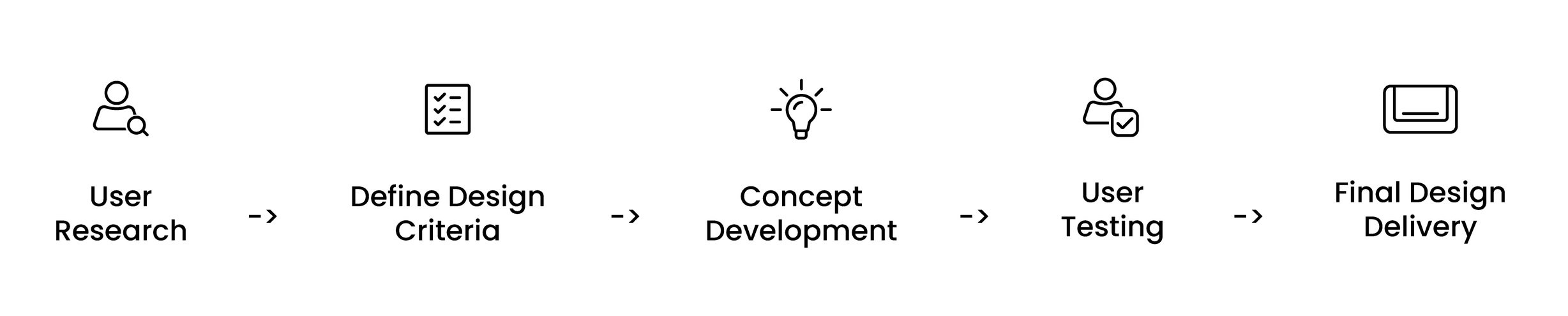

Define Design Criteria

I worked with Volta Lab to define the design constraints for the machine and its internal consumables, understanding the functionalities, user needs, and pain points.

How do we simplify a complex machine through design while ensuring its accessibility and ease of use?

Concept Development Process

Sketch ExplorationI explored different forms of the machine, taking into account features such as door mechanics, screen placement, and machine ergonomics. The forms aim to feel scientific and hygienic while maintaining a minimal , simple, and approachable look.

Door Mechanical ExplorationOne major ergonomic challenge is the accessibility of the door during operation due to its large size and coordination with the screen. I experimented with different door interactions and simulated their movements through CAD assemblies to test the total height of the machine in opened state as well as the linkage mechanisms required to achieve the movements.

Form RefinementI worked with the Spatial Dynamics team to project some of the sketch concepts into CAD to refine the proportion and scale of the design. We looked specifically at the handle transition, indicator light placements, angled top, color blocking, sealing and etc..

Ergonomic PrototypeTo better understand the ergonomics of the design, I picked three main concepts and built physical prototypes for the interior and exterior of the machine. Due to the large size, I designed the mockups to be modular where each design can magnetically snap to the main chassis.

User Interface Re-design

While weighing the options for screen size and positioning and assisting the user tests, I redesigned the original interface to adapt to new machine features. With each ratio and size option comes challenges for communicating the machine workflow intuitively and ergonomically.

User Testing

We conducted internal user tests at Volta Lab with these models, focusing on the accessibility, visibility, and ergonomics of the door, screen, and internal labware handle designs. The participants came from various backgrounds, from bio-researcher, to engineers, to marketing professionals to reflect the end user populations. I created custom UI for each design that simulated the machine workflow and prompted the users to interact with different parts of the machine.

Mechanical Exploration

At the same time, I explored different hardware options that would allow for easy and smooth door interaction. To simulate the weight of the machine, I re-constructed the winner concept from the user testing out of plywood, integrating a four bar linkage and gas spring to assist the lifting and bi-state positioning of the door.

Final Design

The final design incorporates a double-hinged door with imbedded screen at the front. The door handle design continues the sheet metal aesthetic and is further accentuated through the sleek status light bar above.

The machine door offsets slightly above the main body to create a clear visual divide, making the originally large machine seems more contained and sleek visually.

Machine Interior

The interior design aims to simplify the mechanical appearance of the gantry system while maintaining a visually simple and hygienic look. We incorporated ergonomic features from the research into the labware and internal cover, highlighting points of interaction (labwares) and hiding the automation mechanics.

The perception of simplicityCallisto is a very complex machine with a lot of complex user interaction points, the appearance and form aim to provide easy navigation among the screen, labware and other machine features.

Guided operation through UIMachine UI prompts users to interact with different parts of the machine. Human error is a common reason for inaccurate results. Synchronizing the physical and digital interface is pivotal in lowering user’s cognitive load

Compatible Internal LabwareLabware designs are highly mobile units within the machine. Their ergonomics are informed by the overall machine architecture. To maintain the simplicity of the interior, the ergonomic features aim to appear simple and minimal without visual chaos.

Learning:

Digital and physical interface highly inform each other.

Identifying design priority early helps make effective design decisions.

When building large mockups, modularity is key to efficient transportation and iteration

Understanding the variables conditions of the product environment is pivotal for good ergonomics