Reekon Tools

I worked as an industrial design intern for Reekon Tools, a company that streamlines construction workflow through digitized measuring devices. I helped design the holster for T1 Tomahawk, a digital tape measure and led the R&D product development.

Info:

Internship, 2022 Summer, 6 weeks

Reekon Tools

Supervisor/Teammate

Konstantinos Oikonomopoulos

Christian Reed Bartlomiej Saminski

Market/User Research to define product features; Create concept sketches, mockups, CAD for form investigation; Design the tape measure holster for manufacturing

Skills:

Industrial Design; Packaging Design; Product Prototyping

Tools:

Solidworks; Illustrator; 3D Printing; Sewing

Role:

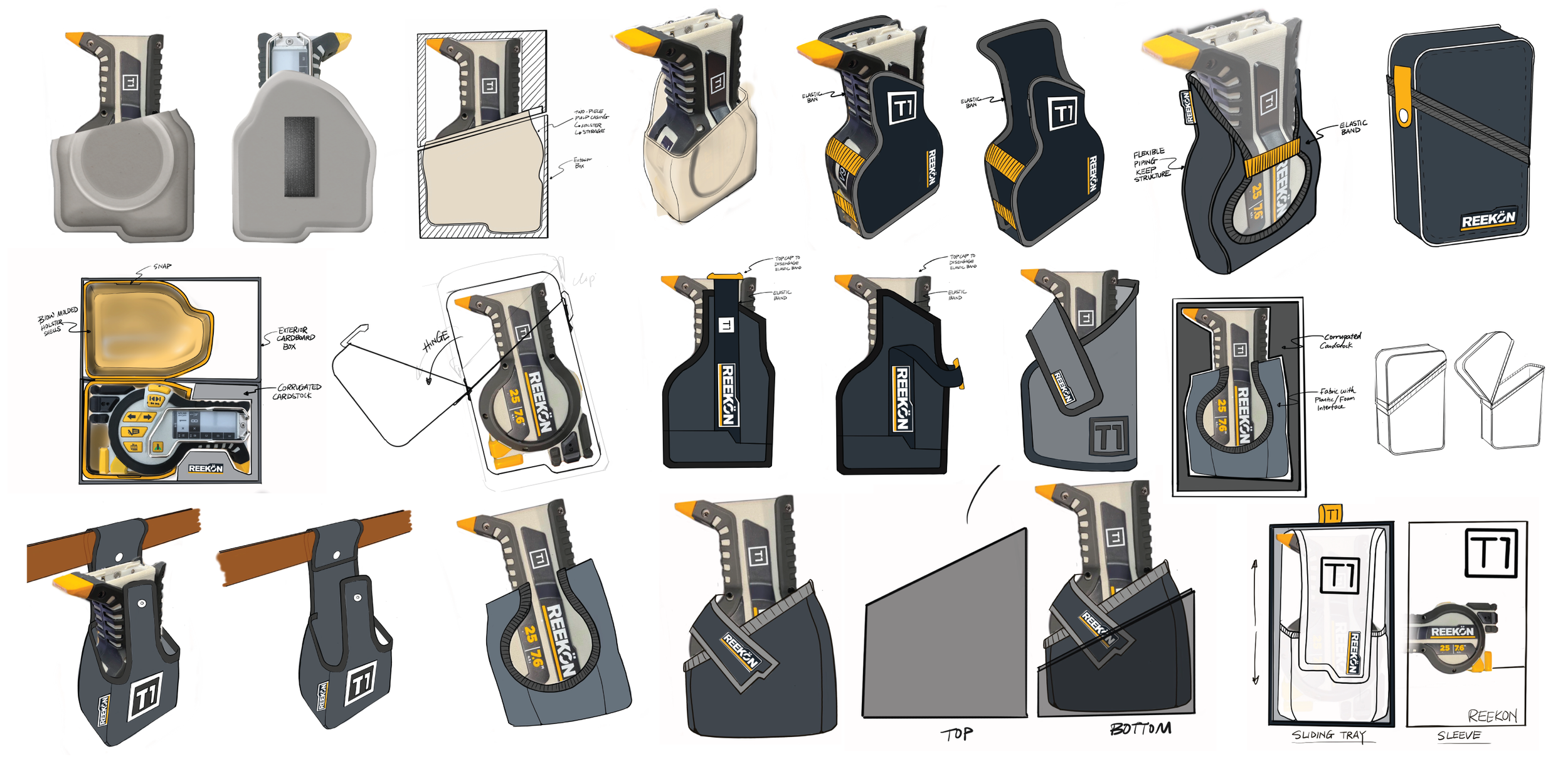

Holster Design Challenge

Protects and secures the device

Low manufacturing cost

Reusable

Withstand harsh environmental conditions

Brand Positioning

Looking at the current construction tool market, most brands are driven by a rugged and functional look with distinct color highlights. Based on Reekon’s product direction and pricing, they situate as as a niche and premium tool brand that prioritizes utility and ease of use.

Paper Pulp

Tool Pouch

EVA Foam

EPP Foam

Cardboard / Plastic Shell

Plastic Toolbox

Material Research

The material option highly hinges on its manufacturing cost and potential for additional value creation. The packaging should not only communicate the brand and protects the device, but also reflect the utilitarian feel of the product. Additionally, we want to extend the lifespan of the packaging beyond initial unboxing, creating a more long lasting impact on the product user experience.

Concept Development

To explore the longevity and usability of the packaging experience further, I pushed for the design of a holster that would secure and stores the device when not in use while fully accessible during use.

The initial concept development focuses on the ergonomics, manufacturability, and branding of the holster design. I explored various unholstering interactions and potential material/hardware that would best support the design. I also identified the most vulnerable parts of the device that require protection and parts that could be exposed for easier accessibility.

Initial Holster Construction

To achieve an effective level of rigidity and flexibility, we narrowed down the holster construction that is composed of flexible thin plastic core molded into form and encased by tough nylon fabric. After the first round of concept selection, I picked first four concepts and worked to build prototypes that best simulate the behaviors of the intended fabrication methods.

Hardware Exploration

One major consideration is the (un)holstering mechanism that would allow quick handle access during frequent use as well as secure protection of the device when resting on a tool belt or stored in a tool bag.

Proposal 1: BuckleLeveraging the buckle’s open and closed states to push the holster apart to pull out device and pull the holster tight to secure the device in.

Proposal 2: LatchInspired by the snow boots mechanism, the latch effectively secures the device with a simple pivoting mechanism. Additionally, the “wrapped-around” architecture creates opportunity for an opening at the tape outlet, allowing users to pull out tape while the device is in the holster.

Form Refinement & Branding

After identifying the overall holster architecture, I worked to refine the form, finalizing the specific angles to ensure consistency. The holster aims to complement the look and branding of the device without creating visual clutter or compositional mismatch.

The holster design intentionally exposes the Reekon logo, allowing the device to provide the main branding feature for the holster.

Manufacturing

During each round of concept iteration, I worked with manufacturers to create fabrication samples based on spec packs detailing the dimensions, construction method and colors & materials of the designs. These samples effectively informed us of fabrication limitations and material behaviors.

An Iterative Process

The iteration process helped us narrow down the required holster thickness and construction methods to ensure good rigidity. It also informed us of the optimum positioning of the hardware and additional reinforcements for good device security.

Low ProfileMaintaining a minimal footprint allows for cost-effective batch shipping as well as consistent design language between the device and the holster.

Intuitive User InteractionThe overall design aims to keep a simple and minimal aesthetic, placing highlight color at the main interaction point for quick access.

Mobile DesignT1 Tomahawk is a relatively large and heavy measuring gadget, therefore, the holster plays a major role in creating comfort and mobility when the user carry around their body.